As the demand for high-energy-density lithium-ion batteries grows, the risk of thermal runaway becomes a primary engineering challenge. Thermex battery module protection refers to a specialized suite of materials and design strategies engineered to isolate heat and prevent the propagation of fire between individual cells. Without robust protection, a single cell failure can trigger a chain reaction, leading to catastrophic module failure. By implementing high-performance thermal barriers, manufacturers can ensure that heat is dissipated efficiently during normal operation while providing a "firewall" effect during emergency scenarios.

Modern battery packs are often subject to extreme environmental conditions and rapid charging cycles, both of which generate significant internal heat. Thermex solutions utilize advanced composite materials, such as aerogels, ceramic fibers, and intumescent coatings, to maintain structural integrity. These materials are chosen for their low thermal conductivity and high dielectric strength, ensuring that the electrical system remains insulated even under intense thermal stress.

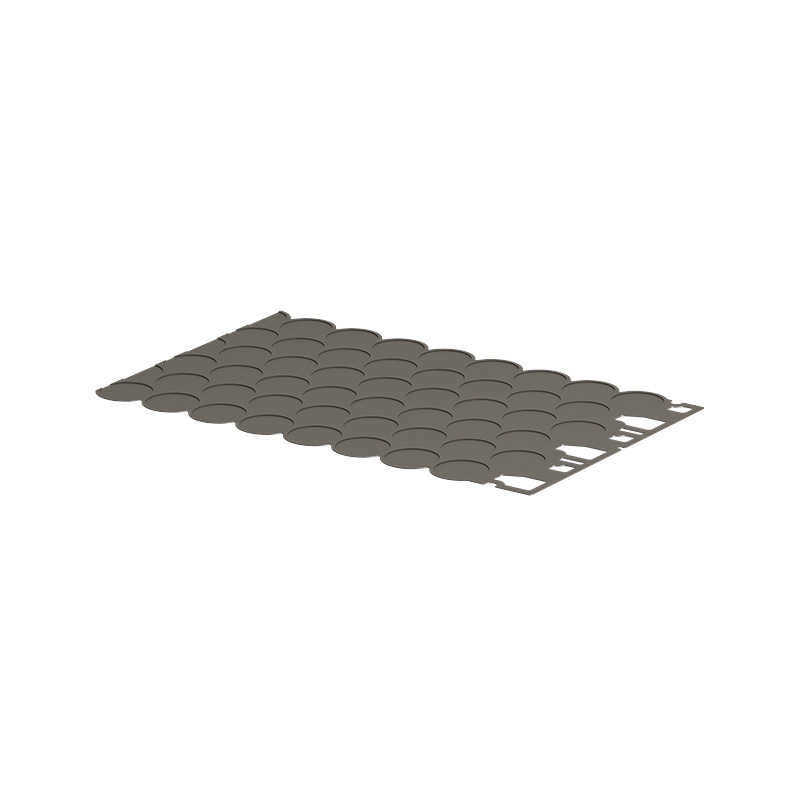

Aerogels are frequently utilized in Thermex applications due to their status as one of the lightest and most effective thermal insulators available. These spacers are placed between cells to absorb the expansion forces of the battery (swelling) while providing a barrier that prevents heat from transferring to adjacent cells. This compression management is vital for the longevity of the battery module, as it maintains the physical alignment of the cells throughout their lifecycle.

Intumescent materials provide a secondary layer of protection by expanding when exposed to high temperatures. This expansion creates a charred, insulating layer that physically blocks flames and reduces the rate of heat transfer. These coatings are often applied to the module housing or internal dividers to create a "sealed" environment that contains any potential thermal event within a localized area.

Selecting the right Thermex protection requires a balance between weight, thickness, and thermal resistance. The following table compares common materials used in module protection to help engineers determine the best fit for their specific energy density requirements:

| Material Type | Thermal Conductivity (W/m·K) | Maximum Temp (°C) | Primary Benefit |

| Silica Aerogel | 0.015 - 0.025 | 650°C | Ultra-thin profiling |

| Ceramic Paper | 0.05 - 0.12 | 1200°C+ | Extreme heat resistance |

| Mica Sheets | 0.30 - 0.50 | 1000°C | Dielectric strength |

| Silicone Foam | 0.06 - 0.10 | 250°C | Compression/Vibration |

Effective Thermex battery module protection is not just about material selection; it is about the strategic integration of these materials into the battery's architecture. To achieve maximum safety, manufacturers follow several practical design principles:

By focusing on these practical applications, the industry can move toward "zero-propagation" battery packs, where a single cell failure does not lead to a total vehicle loss. This level of protection is essential for consumer confidence and the global transition to electric mobility.

Applet

Applet

Call Center:

![]() Tel:+86-0512-63263955

Tel:+86-0512-63263955

![]() Email :[email protected]

Email :[email protected]

Copyright © Goode EIS (Suzhou) Corp LTD

Insulating Composite Materials and Parts for Clean Energy Industry

Insulating Composite Materials and Parts for Clean Energy Industry

cn

cn English

English