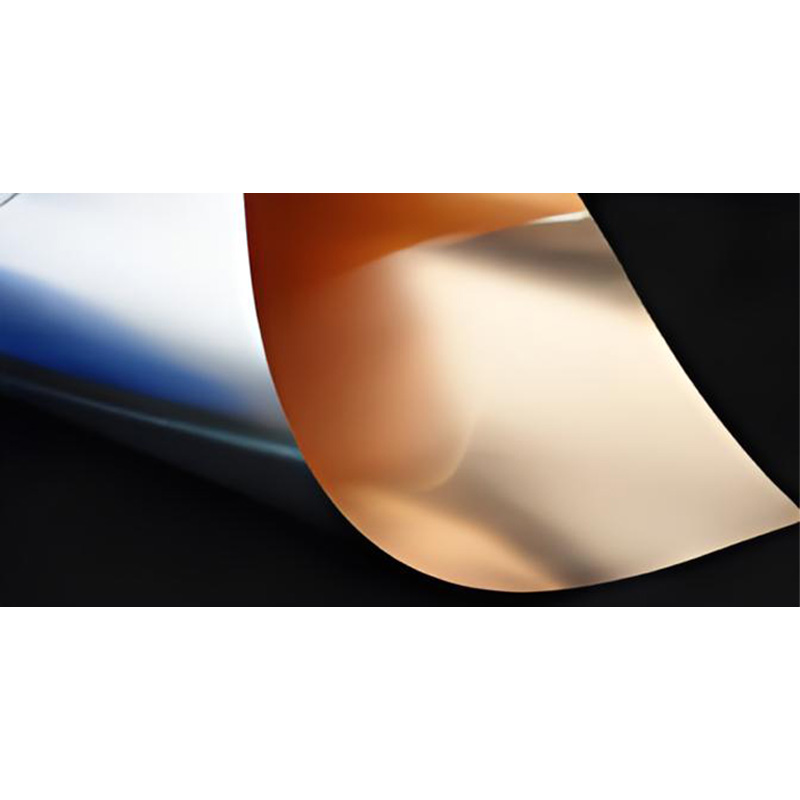

Precision Copper Aluminum Foil serve as the foundational current collectors in lithium-ion batteries and supercapacitors. Unlike standard industrial foils, precision-grade materials are engineered to maintain ultra-thin profiles—often reaching thicknesses as low as 4.5 microns for copper and 10 microns for aluminum. This reduction in thickness is critical for increasing the energy density of battery cells, as it allows for more active material to be packed into the same volume. The precision aspect refers not just to thickness, but to the uniformity of the surface tension and the absence of microscopic pinholes, which ensures stable electron transport during high-speed charging and discharging cycles.

The manufacturing process for these foils involves sophisticated cold-rolling techniques or electrodeposition. For precision copper foil, electrodeposition is frequently used to achieve a specific surface roughness on one side, which enhances the adhesion of the graphite anode slurry. Aluminum foil, conversely, is typically rolled and treated to form a passivating oxide layer that prevents corrosion when in contact with acidic electrolytes. These material properties are essential for the longevity of electric vehicle (EV) batteries and grid-scale storage solutions.

When selecting precision foils for industrial applications, engineers must balance mechanical strength with electrical conductivity. The following table highlights the typical specifications for high-performance precision foils used in the electronics and energy sectors:

| Property | Precision Copper Foil | Precision Aluminum Foil |

| Standard Thickness | 6μm - 12μm | 10μm - 20μm |

| Tensile Strength | ≥ 280 MPa | ≥ 150 MPa |

| Electrical Conductivity | ≥ 97% IACS | ≥ 61% IACS |

| Surface Roughness (Rz) | 0.5μm - 3.0μm | < 0.5μm |

The surface of precision foils is rarely "smooth" in a traditional sense. In battery applications, copper foil undergoes a "nodularization" process where tiny copper spikes are deposited on the surface to increase surface area. This mechanical interlocking is vital to prevent the delamination of the anode material. Aluminum foil, used for the cathode, often receives a carbon coating to reduce contact resistance and protect the metal from the high potentials required by high-nickel cathode chemistries.

Achieving the "precision" label requires rigorous control during the post-production slitting process. Because these materials are incredibly thin, they are susceptible to edge burrs, wrinkles, and stretching. High-precision slitting machines equipped with tungsten carbide blades are used to ensure that the edges are perfectly straight and free of metallic debris. Any microscopic shard of metal left on the edge of a copper foil could potentially pierce the battery separator, leading to an internal short circuit and thermal runaway.

Quality control standards for these materials typically include:

The industry is currently moving toward "composite foils," which utilize a polymer core (such as PET or PP) sandwiched between two ultra-thin layers of copper or aluminum. This structure significantly reduces the weight of the current collector and acts as a built-in fuse; if an internal short occurs, the plastic core melts and breaks the circuit, preventing fire. While traditional precision foils remain the industry standard for their high conductivity and established manufacturing routes, composite foils represent the next frontier in safety and light-weighting for the aerospace and premium EV sectors.

Furthermore, the demand for 5G telecommunications is driving the need for Very Low Profile (VLP) copper foils. In high-frequency printed circuit boards (PCBs), the "skin effect" causes signals to travel along the surface of the copper. A rough surface would increase the signal path and cause loss, making the ultra-smooth finish of precision copper foil essential for maintaining signal integrity at millimeter-wave frequencies.

Applet

Applet

Call Center:

![]() Tel:+86-0512-63263955

Tel:+86-0512-63263955

![]() Email :[email protected]

Email :[email protected]

Copyright © Goode EIS (Suzhou) Corp LTD

Insulating Composite Materials and Parts for Clean Energy Industry

Insulating Composite Materials and Parts for Clean Energy Industry

cn

cn English

English