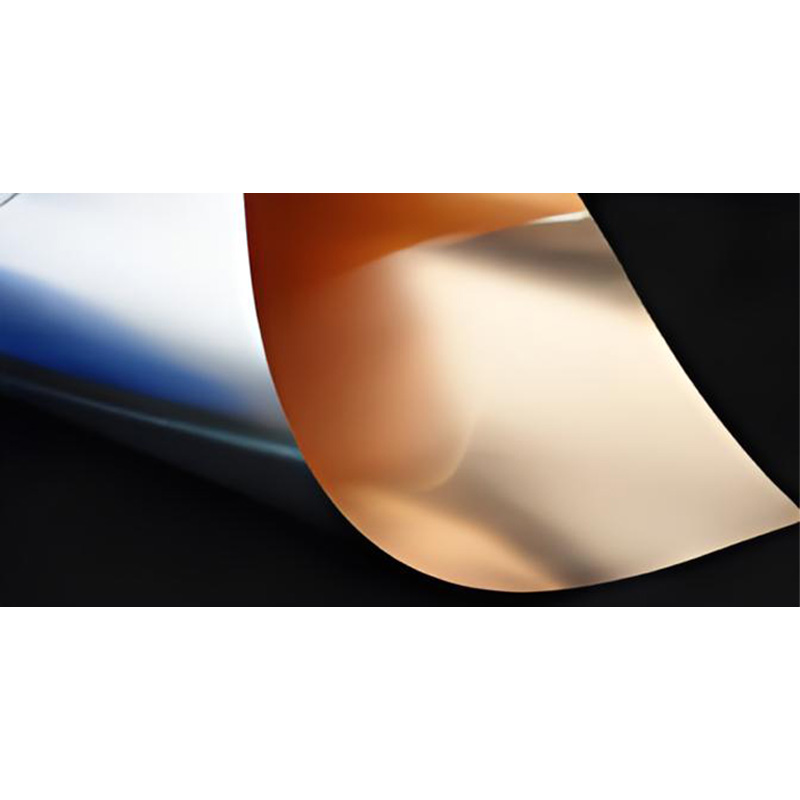

Precision Copper Aluminum Foil serve as the essential current collectors in modern energy storage systems. In a typical lithium-ion battery, high-purity copper foil is utilized as the anode current collector due to its excellent electrical conductivity and electrochemical stability at low potentials. Conversely, aluminum foil is the standard for the cathode, as it forms a protective passivating oxide layer that prevents corrosion at higher voltages. The "precision" aspect refers to the ultra-thin gauges—often reaching as low as 4.5 microns for copper—which allow manufacturers to reduce the inactive weight of the battery, thereby increasing the overall energy density and extending the range of electric vehicles.

| Property | Precision Copper Foil | Precision Aluminum Foil |

| Common Thickness | 4μm - 12μm | 10μm - 20μm |

| Tensile Strength | ≥300 MPa | 150 - 280 MPa |

| Purity Level | 99.9% + | 99.3% - 99.8% |

The production of precision foil requires advanced rolling or electrodeposition techniques to ensure thickness uniformity across the entire width of the roll. Surface topography is equally vital; foils must possess a specific roughness (Rz value) to enhance the mechanical adhesion of the active material slurry. For copper foil, manufacturers often apply a micro-roughened layer or a specialized anti-oxidation coating to prevent degradation during the high-temperature drying processes. For aluminum, high-precision rolling mills ensure a "pinhole-free" consistency, which is crucial for maintaining the structural integrity of the cell over thousands of charge cycles.

Beyond energy storage, precision copper foils are the backbone of the printed circuit board (PCB) industry, particularly for high-frequency and high-speed signal transmission. In the 5G era, "Low Profile" (LP) and "Very Low Profile" (VLP) copper foils are required to minimize the "skin effect" losses that occur at higher frequencies. Aluminum foils, while less common in signal traces, are increasingly used in electromagnetic shielding (EMI) and heat dissipation components within smartphones and data centers. The combination of lightweight properties and thermal conductivity makes precision aluminum an ideal choice for shielding sensitive components from interference while managing the heat generated by powerful processors.

The industry is shifting toward a more sustainable lifecycle for precision foils. Both copper and aluminum are highly recyclable, and advancements in "green" electroplating have reduced the water and energy consumption during the copper foil manufacturing process. Furthermore, the push for thinner foils (down-gauging) directly contributes to resource efficiency, as less raw material is required to achieve the same surface area for electrochemical reactions. This trend not only lowers the bill of materials for manufacturers but also aligns with global initiatives to reduce the carbon footprint of the electronics and automotive supply chains.

Applet

Applet

Call Center:

![]() Tel:+86-0512-63263955

Tel:+86-0512-63263955

![]() Email :[email protected]

Email :[email protected]

Copyright © Goode EIS (Suzhou) Corp LTD

Insulating Composite Materials and Parts for Clean Energy Industry

Insulating Composite Materials and Parts for Clean Energy Industry

cn

cn English

English