Maintaining a reliable vehicle starts with the health of your battery terminals. Car battery electrical connector protection is essential because the engine bay is a harsh environment characterized by extreme temperature fluctuations, moisture, and chemical exposure. Without proper shielding, the lead or lead-alloy terminals react with hydrogen gas released during charging, leading to the buildup of lead sulfate or aluminum sulfate. This crusty white or bluish-green powder acts as an insulator, increasing electrical resistance and eventually preventing your car from starting.

Robust protection for battery interfaces ensures that the alternator can efficiently charge the battery while providing a steady flow of current to critical systems like the ECU, headlights, and infotainment. By implementing a proactive maintenance strategy, vehicle owners can extend the lifespan of both the battery and the expensive wiring harnesses connected to it.

One of the most common ways to achieve automotive terminal insulation is through the use of specialized aerosol protectors or dielectric grease. These products create an airtight seal over the metal surfaces, preventing oxygen and moisture from reaching the connection points. High-quality terminal protectors often leave a red or clear tacky film that stays flexible even in sub-zero temperatures, ensuring the seal remains intact despite engine vibrations.

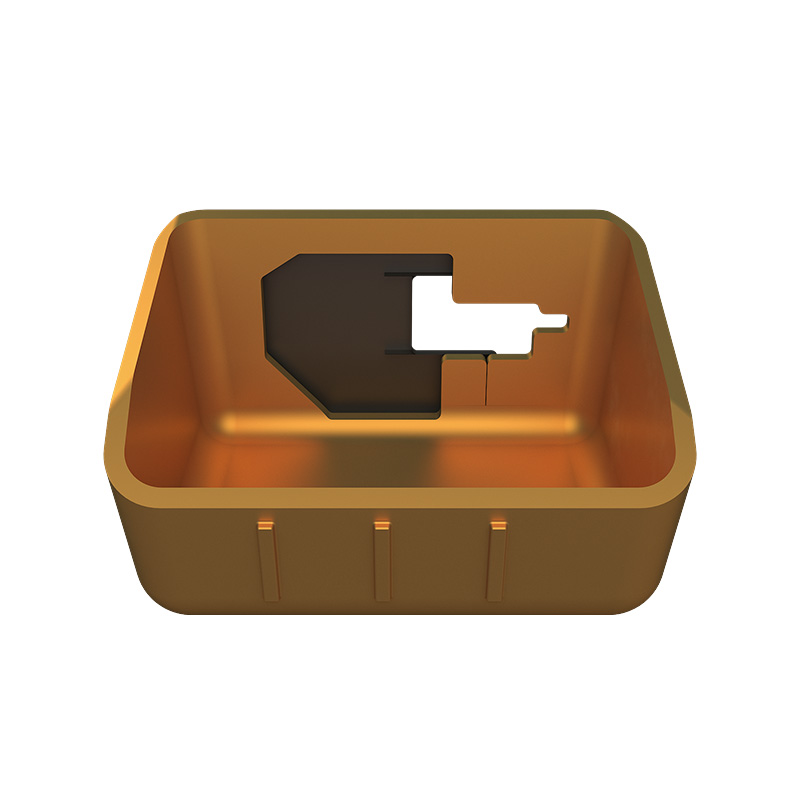

Physical barriers play a significant role in long-term battery cable end preservation. Chemically treated felt washers, usually color-coded red for positive and green for negative, are placed at the base of the battery post to neutralize acid fumes. Additionally, rubber or plastic terminal boots provide a mechanical shield against tool slips (preventing accidental shorts) and road debris.

To ensure your car battery electrical connector protection is effective, you must start with a surgically clean surface. Applying protectants over existing corrosion will only trap the acid and continue the degradation process. Follow these industry-standard steps for the best results:

Not all protection methods are created equal. Depending on your climate and driving habits, some solutions may be more effective than others. The table below compares the most popular options for securing your vehicle's electrical integrity.

| Protection Method | Primary Benefit | Durability |

| Dielectric Grease | Moisture exclusion and easy application | Medium (Requires re-application) |

| Aerosol Sealant | Complete airtight coverage | High (Resists wash-off) |

| Felt Washers | Acid vapor neutralization | Very High (Lasts years) |

| Rubber Boots | Physical impact and short-circuit protection | Permanent (Unless torn) |

When shopping for car battery electrical connector protection, look for products that specify "high dielectric strength" and "thermal stability." In regions with heavy salt usage during winter, a heavy-duty wax-based sealant is often superior to simple grease, as it won't attract road grit that can become abrasive. For high-performance or off-road vehicles, ensure the protection method can withstand significant vibration without cracking or peeling away from the metal surface.

Investing a few dollars in terminal protection today can save hundreds of dollars in future repairs, including alternator replacements and diagnostic fees for "ghost" electrical issues that are often just the result of a poor connection at the battery source.

Applet

Applet

Call Center:

![]() Tel:+86-0512-63263955

Tel:+86-0512-63263955

![]() Email :[email protected]

Email :[email protected]

Copyright © Goode EIS (Suzhou) Corp LTD

Insulating Composite Materials and Parts for Clean Energy Industry

Insulating Composite Materials and Parts for Clean Energy Industry

cn

cn English

English