Thermex battery module protection represents a critical leap in energy storage safety, specifically designed to mitigate the risks of thermal runaway in high-density lithium-ion systems. This technology functions as a sophisticated thermal barrier, utilizing advanced phase-change materials and high-performance insulation to isolate individual cells. By creating a thermal "firewall" between modules, Thermex ensures that if a single cell experiences a short circuit or overheating event, the excess heat energy is absorbed and dissipated before it can trigger a chain reaction in neighboring cells. This containment is essential for maintaining the structural integrity of the entire battery pack during extreme operating conditions.

The efficacy of Thermex protection lies in its unique material science, which often incorporates silicon-based elastomers or specialized ceramic fibers. These materials are engineered to be lightweight yet provide exceptional fire resistance and low thermal conductivity. Unlike traditional insulation, Thermex solutions are often compressible, allowing them to double as vibration dampeners within the battery housing. This dual-purpose design protects the delicate internal chemistry of the battery from both the intense heat of an electrical fault and the mechanical stresses of daily transportation and high-impact scenarios.

To appreciate the value of Thermex protection, it is helpful to compare its performance against standard battery insulation methods. While basic foam or plastic spacers provide structural support, they often fail when temperatures exceed 200°C. Thermex modules are designed to withstand temperatures far exceeding the point of lithium-ion combustion, providing a critical window for emergency systems to engage or for occupants to exit a vehicle safely. The following table highlights the technical advantages found in Thermex-enhanced systems.

| Feature | Standard Insulation | Thermex Protection |

| Melting Point | Low (120°C - 180°C) | High (>1000°C) |

| Gas Venting | Obstructed | Directional Channeling |

| Weight Impact | Moderate | Minimal/Optimized |

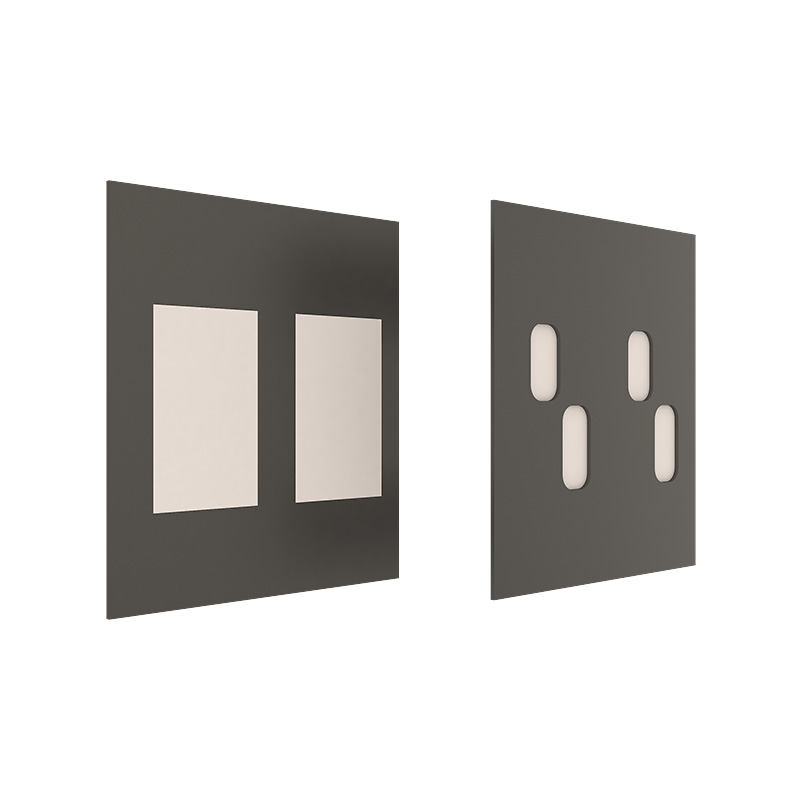

Integrating Thermex protection into an EV battery pack involves precise engineering during the module assembly phase. Manufacturers apply these protective layers as thin sheets or molded gaskets between every cell. This architectural choice is not just about safety; it also improves the longevity of the battery. By normalizing the temperature across the entire module, Thermex reduces "hot spots" that typically lead to uneven cell degradation. Consequently, batteries equipped with these protection layers often exhibit better capacity retention over hundreds of charge cycles, providing a better return on investment for the end user.

As the industry moves toward solid-state batteries and even higher energy densities, the role of Thermex battery module protection becomes even more pivotal. Future iterations of this technology are expected to incorporate "smart" materials that change their thermal properties in response to real-time temperature fluctuations detected by the Battery Management System (BMS). By combining passive physical barriers with active sensing, Thermex is setting a new benchmark for what it means to have a secure and reliable energy storage system in the modern age.

Applet

Applet

Call Center:

![]() Tel:+86-0512-63263955

Tel:+86-0512-63263955

![]() Email :[email protected]

Email :[email protected]

Copyright © Goode EIS (Suzhou) Corp LTD

Insulating Composite Materials and Parts for Clean Energy Industry

Insulating Composite Materials and Parts for Clean Energy Industry

cn

cn English

English